PF Impact Crusher

PF series crushers adopt the first new manufacturing technology and unique structural design, which can make the crushed finished product cubic, without tension and cracks, good grain shape, and can crush various coarse, medium and fine materials (granite, limestone, concrete, etc.) with a feed particle size of no more than 500mm and a compressive strength of no more than 200MPa. The discharge particle size can be adjusted and the crushing specifications are diversified.

Application scope: various ore crushing, railway, highway, energy, cement, chemical industry, construction and other industries.

applicable materials: granite, limestone, concrete, basalt, iron ore, etc.

Processing capacity: 30-500T/H

Feed particle size: 0-500mm

视频播放失败,请联系站点管理员!

Performance Characteristics

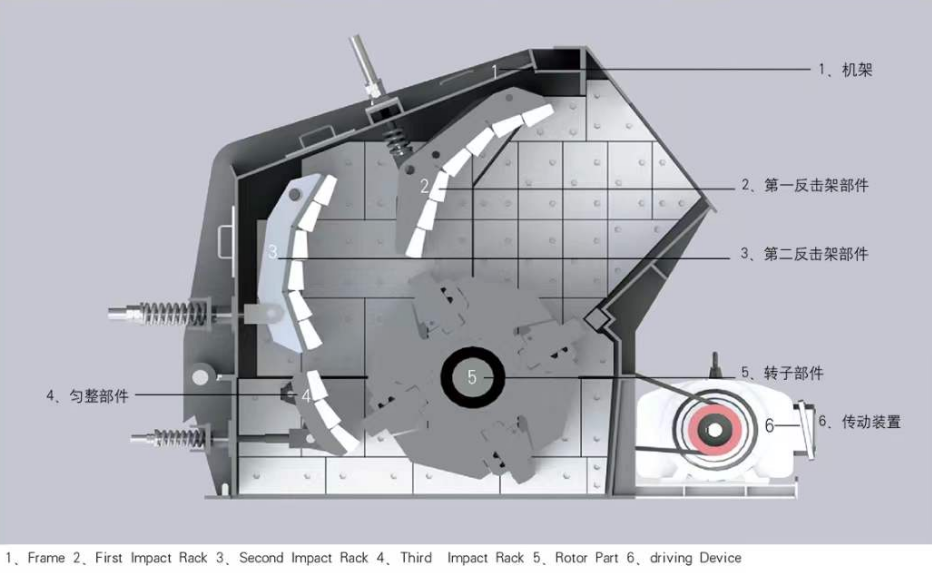

1. Large feed inlet, high crushing cavity, high hardness of suitable materials, large block size and less product stone powder;

2. The clearance between the impact plate and the plate hammer can be easily adjusted, the discharge particle size can be effectively controlled, and the particle shape is good;

3. Compact structure, strong rigidity of the machine and large moment of inertia of the rotor;

4. High chromium plate hammer, impact resistance, wear resistance, impact force;

5. Keyless connection, convenient maintenance, economical and reliable;

6. Full crushing function, high productivity, low wear of parts and high comprehensive benefits.

Technical Parameters

| Model |

rotor size (mm) |

Inlet Size (mm) |

maximum feed side length (mm) |

output (t/h) |

power (kW) |

| PF1007 | φ 1000*700 | 440*730 | 300 | 30-55 | 37/6 |

| PF1010 | φ 1000*1050 | 400*1080 | 350 | 50-80 | 75/6 |

| PF1210 | φ 1250*1050 | 440*1090 | 350 | 70-130 | 110/6 |

| PF1214 | φ 1250*1400 | 400*1430 | 350 | 90-180 | 132/6 |

| PF1315 | φ 1320*1500 | 860*1520 | 500 | 120-250 | 200/6 |

| PF1320 | φ 1320*2000 | 860*2020 | 500 | 160-280 | 250/6 |

| PF1520 | φ 1500*2000 | 900*2020 | 500 | 260-400 | 355/6 |

| PF1820 | φ 1800*2000 | 1270*2020 | 600 | 300-500 | 250*2/6 |

Note: The above contents are for reference only. The actual samples shall prevail. The data in the table are subject to change without prior notice.

Works

PF series products use impact energy to crush materials. When working, the motor drives the rotor shaft through a V-belt. The materials are broken due to the high-speed impact of the plate hammer on the rotating rotor, and are thrown to the counterattack liner to crush again, and then bounce from the counterattack surface to the plate hammer action area to crush again. This process is repeated until the materials are crushed to the required particle size, the material is repeatedly broken from the feed inlet to the first and 2. three counterattack cavities. When the crushed ore size is less than the gap between the hammer head and the counterattack plate, it is discharged from the lower part of the body, which is the crushed product.