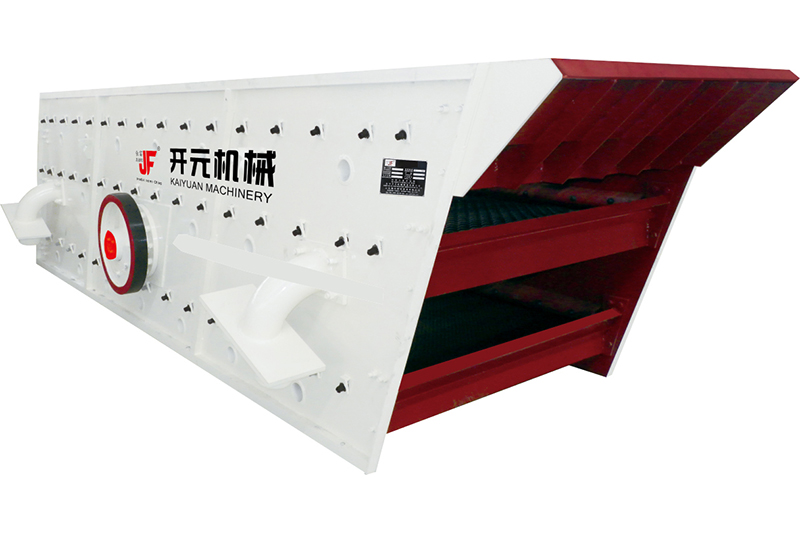

YA/YK Vibrating Screen

Series vibrating screen, with circular vibration track, is specially designed for quarry screening and stone, and can also be used for product classification in coal preparation, mineral processing, building materials, electric power and chemical departments. The screen machine has the characteristics of advanced structure, strong excitation force, low vibration noise, easy maintenance, sturdiness and durability. The vibrating screen produced by our company is at the advanced level at home and abroad and is highly praised by users in various industries. The material screening line of this model is long, the screening specifications are many, the specifications of each file are clearly screened, the screening efficiency is high, and it is not easy to block. It has the advantages of reasonable structure, strong excitation force, low vibration noise, sturdiness and durability, convenient maintenance, safe use, etc.

Application scope: mining, building materials, transportation, energy, chemical and other industries.

Applicable materials: various soft and medium hard ores, construction waste, tailings, steel slag, coal

Processing capacity: YA series 32-810T/H YK series 32-1200T/H

视频播放失败,请联系站点管理员!

Performance Characteristics

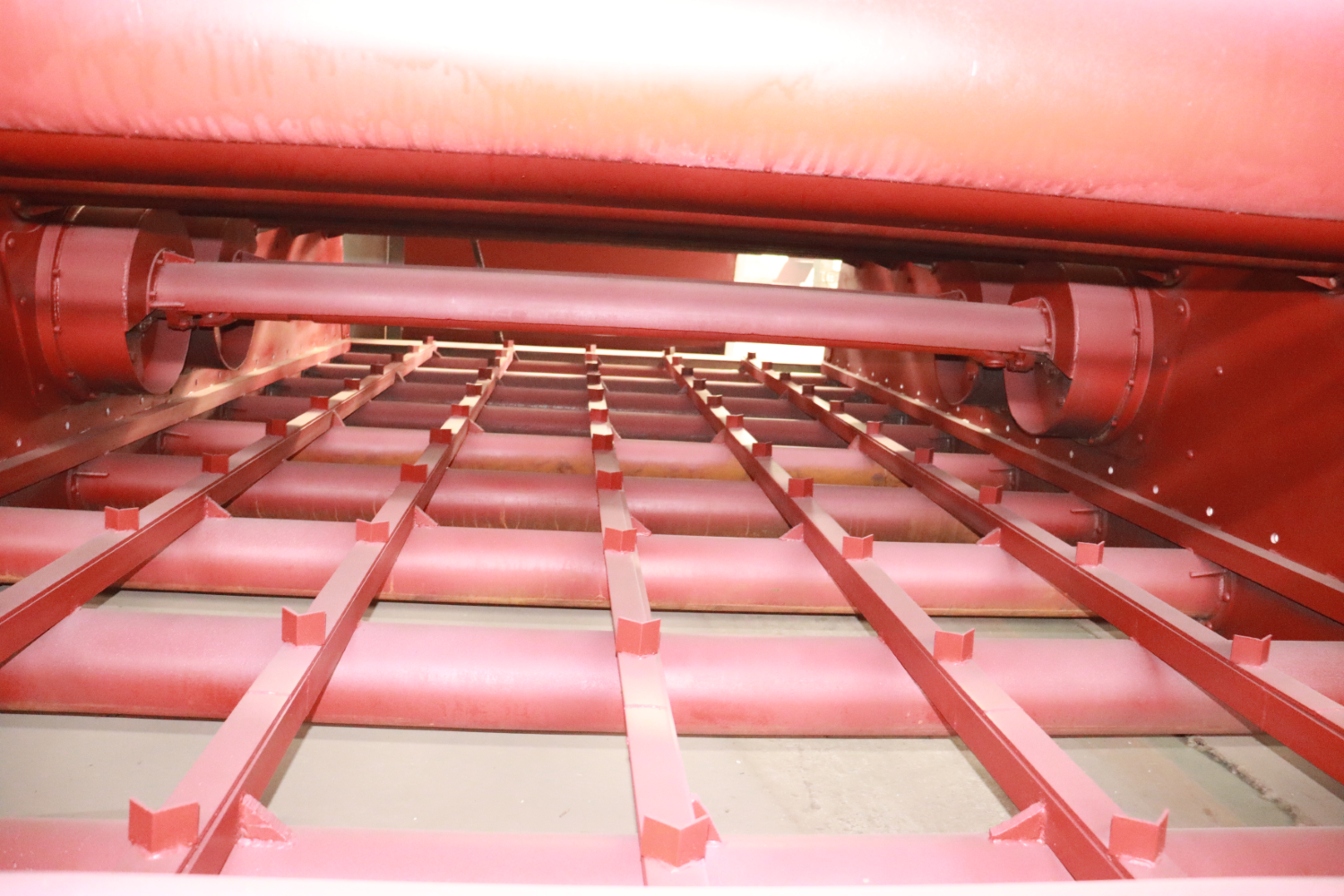

Is small in size, light in weight, simple and compact in structure, small in maintenance, and low in operating cost; super-energy vibration exciter, high in screening efficiency, low in vibration and noise, optimized in box structure, reliable in use, optimized in transmission mode, and stable in operation. The screen can be equipped with four layers of screens with different apertures, which can produce five different specifications of finished materials at the same time.

Use And Maintenance

Vibrating screen should be started when there is no material on the screen surface, and the material should be avoided as far as possible. The material can be fed only after the screen runs smoothly. The feeding should be stopped before the shutdown, and the shutdown should be stopped after the surface materials are removed. During the working process, the operation of the screen machine should be observed frequently. If abnormal movement or abnormal sound is found, the machine should be shut down for inspection in time to find out the reason and eliminate the fault.

Technical Parameters

|

ModelModel |

Specification of screen surface |

Number of screen layersNumber Of Screen Layer |

mesh sizeMesh Size (mm) |

maximum feed sizeMax Feed Size (mm) |

outputCapacity (t/h) |

power |

vibration frequencyVibrational Frequency (r/min) |

double amplitudeDouble Amplitude (mm) |

|

2YA1237 |

3700*1200 |

2 |

3-100 |

400 |

10-80 |

4 poles 15 |

750-950 |

5-9 |

|

3YA1237 |

3700*1200 |

3 |

3-100 |

400 |

10-80 |

4 poles 15 |

750-950 |

5-9 |

|

2YA1548 |

4800*1500 |

2 |

3-100 |

400 |

30-200 |

4-pole 18.5 |

750-950 |

5-9 |

|

3YA1548 |

4800*1500 |

3 |

3-100 |

400 |

30-200 |

4-pole 18.5 |

750-950 |

5-9 |

|

2YA1848 |

4800*1800 |

2 |

3-100 |

400 |

50-250 |

4 pole 22 |

750-950 |

5-9 |

|

3YA1848 |

4800*1800 |

3 |

3-100 |

400 |

50-250 |

4 pole 22 |

750-950 |

5-9 |

|

4YA1848 |

4800*1800 |

4 |

3-100 |

400 |

50-250 |

4 pole 22 |

750-950 |

5-9 |

|

2YA1860 |

6000*1800 |

2 |

3-100 |

400 |

65-586 |

4 pole 22 |

750-950 |

5-9 |

|

3YA1860 |

6000*1800 |

3 |

3-100 |

400 |

65-586 |

4 pole 22 |

750-950 |

5-9 |

|

4YA1860 |

6000*1800 |

4 |

3-100 |

400 |

65-586 |

4 poles 30 |

750-950 |

5-9 |

|

2YA2160 |

6000*2100 |

2 |

3-100 |

400 |

81-720 |

4 poles 30 |

700-900 |

5-9 |

|

2YA2170 |

2100 × 7000 |

2 |

3-100 |

400 |

81-720 |

4 poles 30 |

700-900 |

5-9 |

|

3YA2160 |

6000*2100 |

3 |

3-100 |

400 |

81-720 |

4 poles 30 |

700-900 |

5-9 |

|

4YA2160 |

6000*2100 |

4 |

3-100 |

400 |

81-720 |

4 pole 37 |

700-900 |

5-9 |

|

2YA2460 |

6000*2400 |

2 |

3-150 |

400 |

100-810 |

4 poles 30 |

700-900 |

5-9 |

|

3YA2460 |

6000*2400 |

3 |

3-150 |

400 |

100-810 |

4 pole 37 |

700-900 |

5-9 |

|

4YA2460 |

6000*2400 |

4 |

3-150 |

400 |

100-810 |

4 pole 37 |

700-900 |

5-9 |

|

2YA2470 |

7000*2400 |

2 |

3-150 |

400 |

100-810 |

4 poles 30 |

700-900 |

5-9 |

|

3YA2470 |

7000*2400 |

3 |

3-150 |

400 |

100-810 |

4 pole 37 |

700-900 |

5-9 |

|

4YA2470 |

7000*2400 |

4 |

3-150 |

400 |

100-810 |

4 pole 37 |

700-900 |

5-9 |

|

technical parametersTechnical Parameters |

||||||||

|

ModelModel |

Specification of screen surface |

Number of screen layersNumber Of Screen Layer |

mesh sizeMesh Size (mm) |

maximum feed sizeMax Feed Size (mm) |

outputCapacity (t/h) |

power |

vibration frequencyVibrational Frequency (r/min) |

double amplitudeDouble Amplitude (mm) |

|

2YK1860 |

6000*1800 |

2 |

3-100 |

400 |

32-312 |

6 pole 22 |

800-970 |

8-11 |

|

3YK1860 |

6000*1800 |

3 |

3-100 |

400 |

32-312 |

6 pole 22 |

800-970 |

8-11 |

|

4YK1860 |

6000*1800 |

4 |

3-100 |

400 |

32-336 |

6 pole 22 |

800-970 |

8-11 |

|

2YK2160 |

6000*2100 |

2 |

3-100 |

400 |

50-475 |

6 pole 30 |

970 |

8-11 |

|

3YK2160 |

6000*2100 |

3 |

3-100 |

400 |

50-475 |

6 pole 30 |

970 |

8-11 |

|

4YK2160 |

6000*2100 |

4 |

3-100 |

400 |

50-597 |

6 pole 37 |

970 |

8-11 |

|

2YK2460 |

6000*2400 |

2 |

3-100 |

400 |

65-550 |

6 pole 30 |

970 |

8-11 |

|

3YK2460 |

6000*2400 |

3 |

3-100 |

400 |

70-620 |

6 pole 37 |

970 |

8-11 |

|

4YK2460 |

6000*2400 |

4 |

3-100 |

400 |

80-680 |

6 pole 37 |

970 |

8-11 |

|

2YK2470 |

7000*2400 |

2 |

3-100 |

400 |

65-550 |

6 pole 30 |

970 |

8-11 |

|

3YK2470 |

7000*2400 |

3 |

3-100 |

400 |

70-620 |

6 pole 37 |

970 |

8-11 |

|

4YK2470 |

7000*2400 |

4 |

3-100 |

400 |

80-680 |

6 pole 37 |

970 |

8-11 |

|

2YK3072 |

7200*3000 |

2 |

3-150 |

400 |

150-900 |

8-pole 18.5*2 |

700-960 |

8-11 |

|

3YK3072 |

7200*3000 |

3 |

3-150 |

400 |

150-900 |

8 pole 22*2 |

700-960 |

8-11 |

|

3YK40100 |

10000*4000 |

3 |

3-150 |

400 |

600-1200 |

8 poles 45*2 |

700-960 |

10-12 |

Works

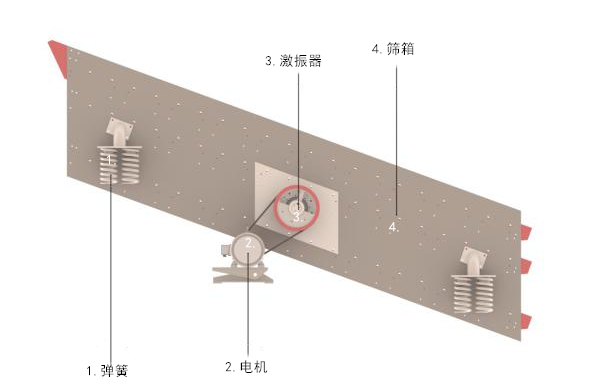

Vibrating screen is mainly composed of a screen box, a screen, a vibrator and a damping spring. The vibrator is installed on the side plate of the screen box, and the motor is driven to rotate through a triangle belt to generate centrifugal force and force the screen box to vibrate. If the user has no special requirements, the woven screen surface is adopted, and the screen surface can meet the requirements of high screening efficiency, long service life and no hole blocking.

Note: The above contents are for reference only. The actual samples shall prevail. The data in the table are subject to change without prior notice.